For an eco-friendly construction industry

New, durable materials and circular production processes: thanks to new professorships, ETH ensures that future infrastructure is built not only to be safe but in ways that protect the environment and the climate at the same time.

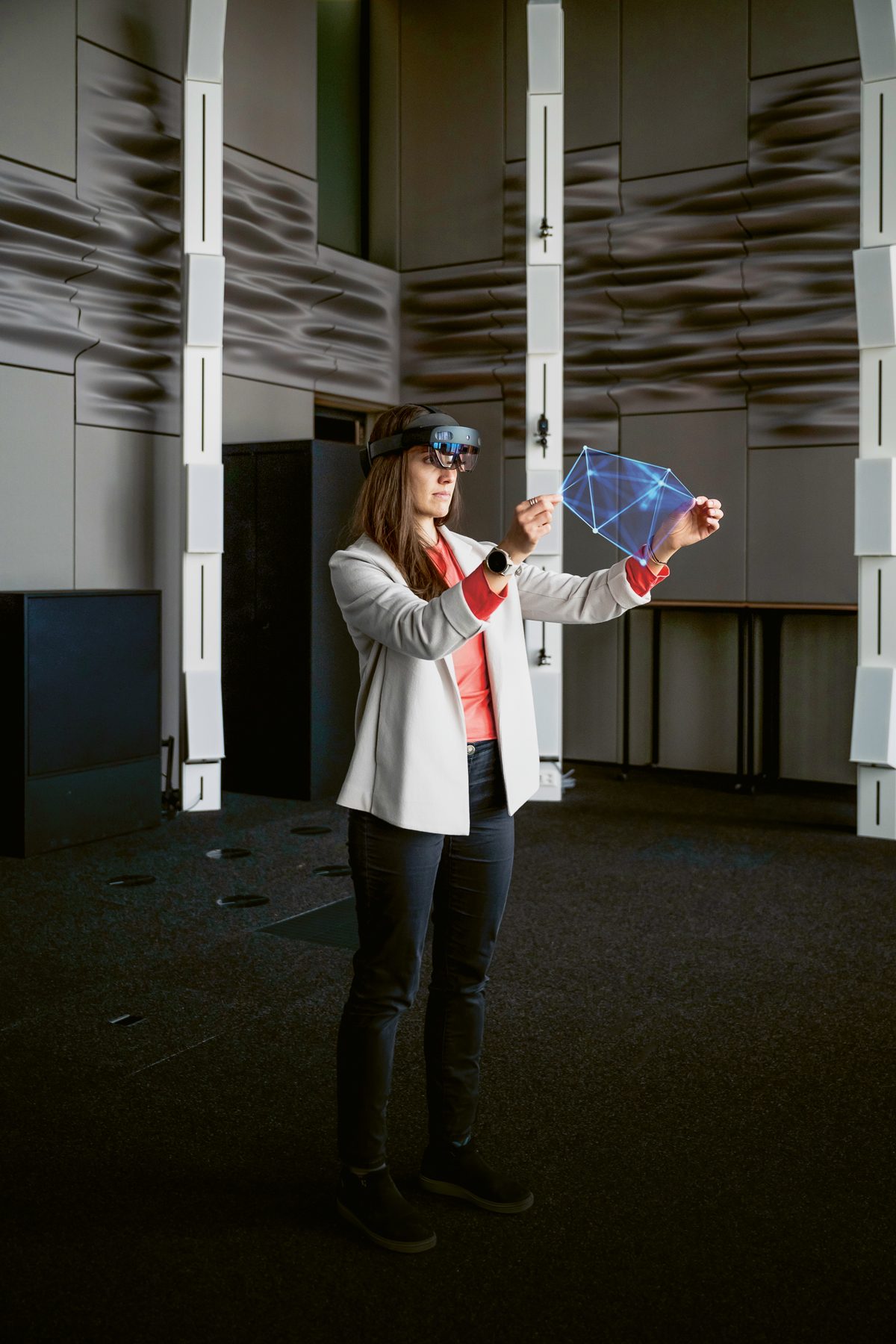

© WSS, Oliver Lang Fotografie

© WSS, Oliver Lang Fotografie

As one of the world’s largest consumers of natural resources and generating high levels of emissions, the construction industry’s footprint is substantial. The concrete-manufacturing industry alone creates around eight percent of global human-made CO2 emissions – around three times as much as aviation. The detrimental effects on biodiversity and the climate are equally high. At ETH, numerous experts are working on finding new ways to build more sustainably in the future, including Professor Ueli Angst, head of the Durability of Engineering Materials group.

New possibilities for corrosion prevention

The bulk of his research focuses on the corrosion processes taking place in large infrastructures made of reinforced concrete. One of the major problems of this material is the corrosion of the inner steel reinforcements which can, in the worst case, lead to the collapse of a bridge or a burst gas pipeline. Preventing corrosion and renovating corroded structures is therefore crucial, but both costly and harmful to the environment. The group led by Ueli Angst is researching the exact mechanisms of corrosion processes. From their findings, the aim is to develop more precise methods for diagnosing, predicting and monitoring corrosion in order that infrastructures either don’t corrode at all or corrode more slowly and can be remediated in good time. This is particularly relevant for Switzerland with its extensive road and rail network and innumerable bridges, tunnels and safety structures located in often inaccessible terrain.

A better understanding of corrosion can also help scientists find the breakthrough needed to develop new, eco-friendly types of concrete. In the future, these concretes could perhaps even function as CO2 sinks – initial projects have already shown promising results. Also important is Ueli Angst’s key role in transferring vital expertise on corrosion to the building specialists of tomorrow; and by supporting spin-offs such as DuraMon, he’s also helping to ensure that the latest research findings are speedily translated into real-world applications.

Research for safer, sustainable materials with longer lifecycles

The planned professorships “Sustainable materials and devices” and “Circular materials for sustainable future infrastructure” also focus on materials and production cycles that are circular and resource-efficient. The key to reducing the environmental impact of material extraction and processing in the construction industry is a circular economy in which new materials are produced on a sustainable basis and used materials are transformed into valuable resources for new products. The “Sustainable Materials and Devices” professorship plans to address the sustainability of the materials themselves and their production, by optimising processes to reduce resource and energy consumption and developing strategies for reuse. Materials that are designed for circularity at the molecular level are particularly attractive when it comes to reuse, as this allows for full recovery of the initial structures and properties.

Composite materials present a particular challenge when it comes to reuse, as it’s often difficult to separate the different materials. In addition, many of the chemical additives used in the materials are hazardous to humans and the environment. The aim of the new “Circular materials for sustainable future infrastructure” professorship is to research and develop solutions to maximise the reuse and recyclability of building materials. Here the focus will be set on identifying easy-to-recycle additives causing little impact to the environment and human health, and on designing new hybrid and composite materials. Such efforts bring the vision of a circular construction industry one step closer.