Building better with robots

Tool manufacturer Hilti funds a professorship at ETH Zurich’s RobotX Center. We talk to Hilti CEO Jahangir Doongaji who explains the reasons for the partnership.

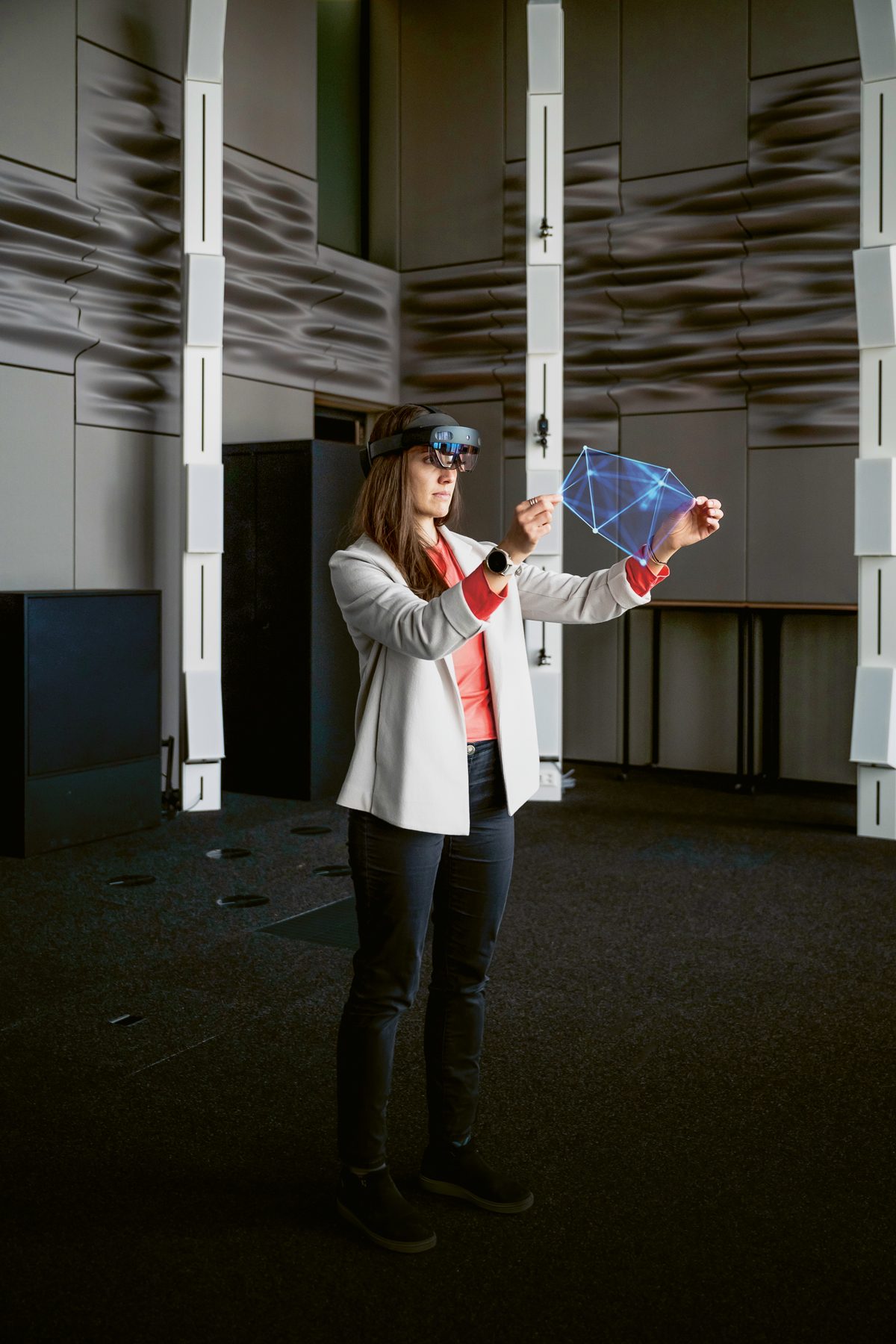

© Hilti / Lukas Gruber

© Hilti / Lukas Gruber

Why is Hilti supporting robotics research at ETH Zurich?

JAHANGIR DOONGAJI – We were already looking into the use of robotics technology in the construction sector back in 2016 and had started looking around for partners to work with us on this challenging development. ETH Zurich is one of the world’s leaders in the field of robotics and, as a Liechtenstein company, Hilti feels a natural affiliation. The university offers us access to the latest findings and outstanding talent, which is why we’ve formed this long-term research collaboration. We’re also funding – together with the Hilti Foundation – a professorship at the RobotX Center, founded in 2019. Joining forces with ETH is also valuable because it’s important for Hilti as a company to be seen as a serious employer in terms of the future technologies of robotics and computer vision. The research partnership with ETH and the involvement of students in the company through internships and Master’s theses reinforce this perception.

Which aspects of research and teaching in the RobotX environment are of particular relevance to Hilti?

Our focus lies in areas like navigation, positioning, control technology, and perception and interpretation of an environment. The activities at the Center are also interesting for many of our innovation fields, such as those around mechatronic and digital solutions.

In recent decades, robots have found their way into many industries in which tasks can be automated – and now they’ve reached the still very traditional construction industry. What is Hilti hoping from robotics here?

The construction industry is undergoing a fundamental transformation. To meet its rising challenges – including inadequate productivity, skilled worker shortage, occupational health and safety requirements, as well as sustainability – the industry is increasingly turning to possibilities offered by digitalisation. This allows processes to be industrialised and automated, with robotics potentially able to make a huge contribution. Our customers are looking for solutions like these, and an increasing number of start-ups are looking at how robotics can be deployed in the construction industry. At Hilti we’re convinced that, with our close customer relations, technical expertise and understanding of applications on construction sites, we can drive developments forward and help our customers through this transformation. They’re the reason why we focus our efforts on transforming new technologies into solutions that will ultimately enable them to build more productively, safely, sustainably and simply “better”.

How should we imagine the interplay between human and robot on construction sites in the future?

Robots such as the Hilti Jaibot, our semi-autonomous drilling robot, enable end-to-end digitalisation of all tasks in a work process: from planning to automatic and precise execution of the tasks through to feedback in the building’s digital model on the work performed. Robots can be used to identify and exploit efficiency potential at many points along the value chain. For example, 500 drilled holes per hour are now feasible. Humans will take on the role of coordinators on the construction site and therefore perform fewer of the tasks themselves. Human-robot collaboration also helps resolve the shortage of skilled workers in the construction industry: new, IT-supported responsibilities, such as operating a robot, make the industry more attractive for young workers. When robots take over the most strenuous tasks – like serial drilling overhead – work on construction sites becomes less physically challenging. It also significantly increases occupational safety.

Let’s finish off with two personal questions for the ETH alumnus: what memories do you have of your studies as a mechanical engineer?

I have great memories of my time at ETH! I feel very emotionally connected to ETH. In those days, coming from India, I had to take the entrance exam and was pretty proud when I cleared that hurdle. At ETH I learned to really learn things, to get to the root of something and not let go until I’d fully understood it. I still benefit from that to this very day. And in terms of interpersonal relations, ETH was formative. I found friends for life at the university. As I’d left my social life behind in India, the friendships I made during the early days in Switzerland and at ETH were all the more important. And I’ll always remain indebted to my professor for fluid dynamics, Hans-Peter Thomann. I wrote my thesis paper under his supervision and also spent some time working at the institute after graduating.

How do you view ETH now?

It makes me proud that we in Zurich have one of the best technical universities in the world. My education at this university has enabled me to pursue a very exciting career and so I’m naturally delighted that two of my three children are now studying at ETH too.